Tame

power

to channel

expertise.

Tame

power

to channel

expertise.

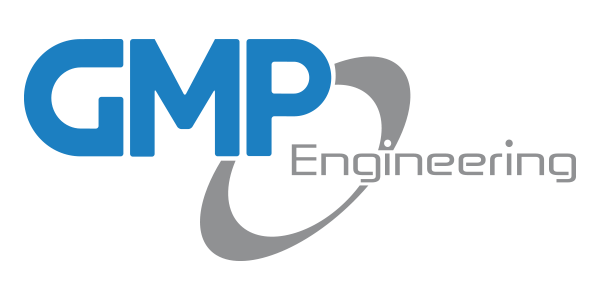

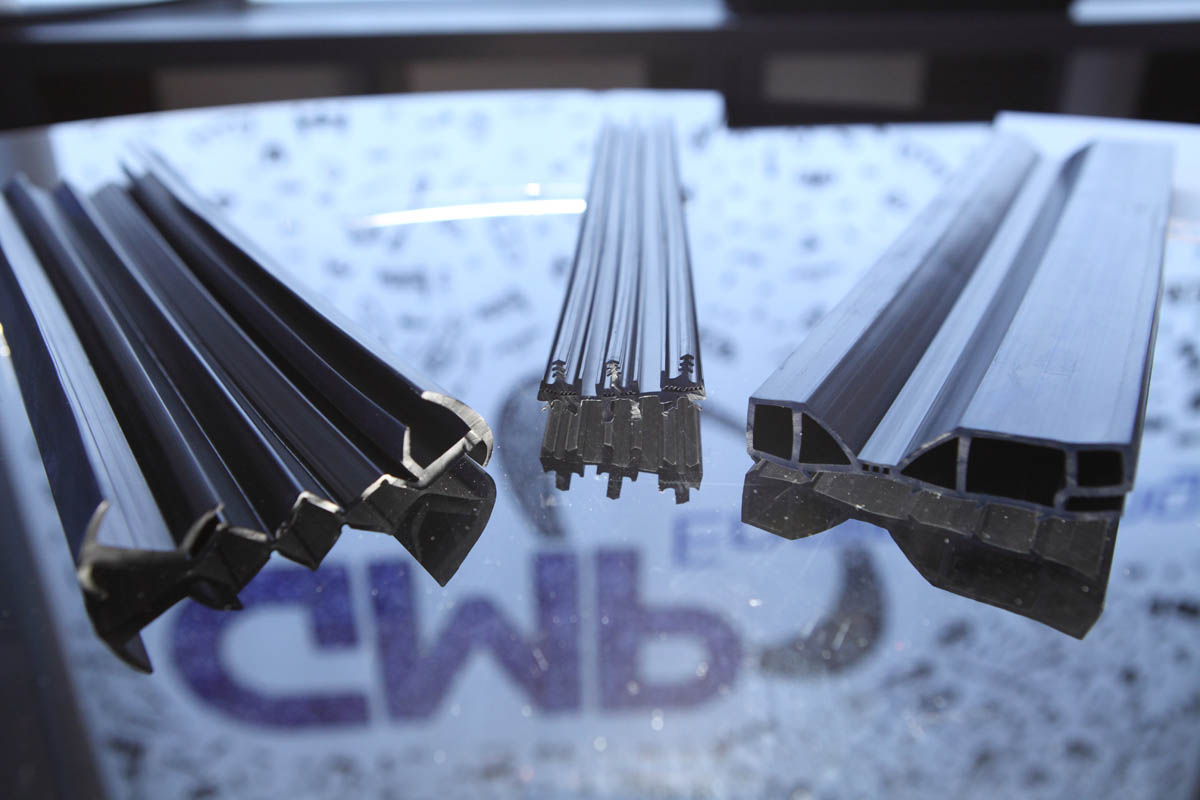

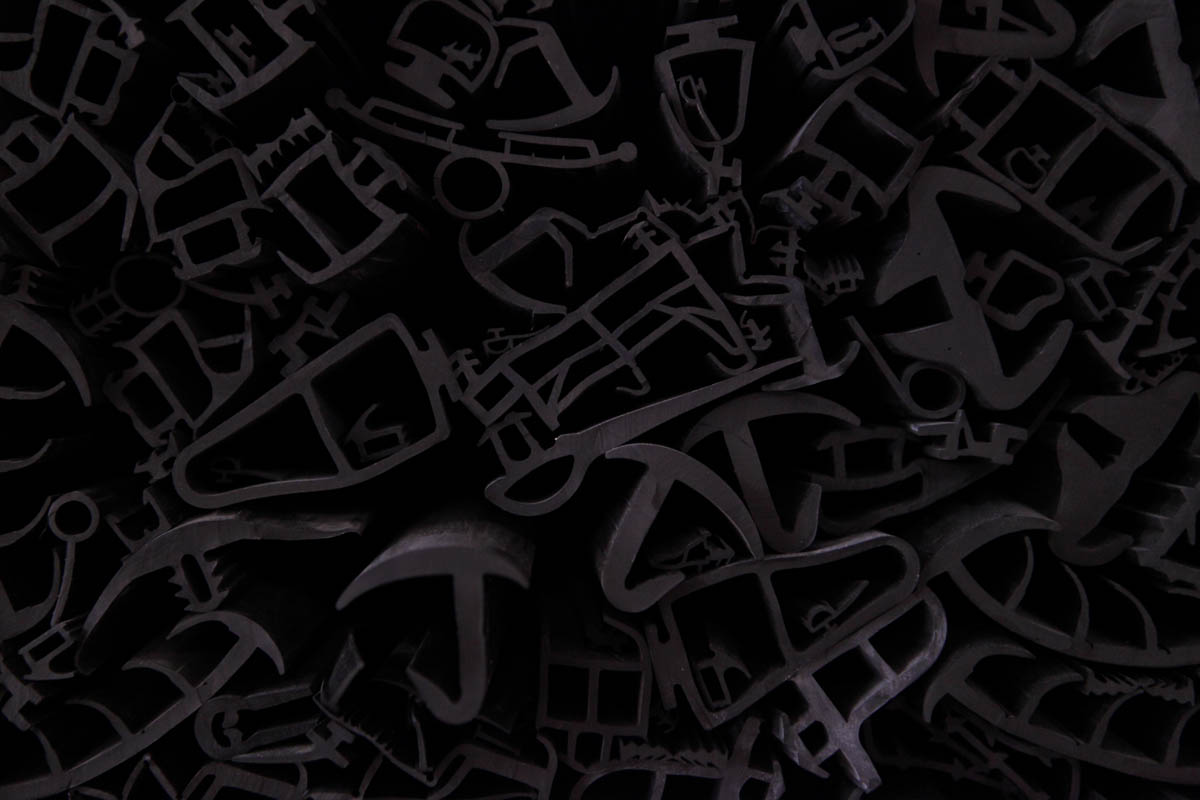

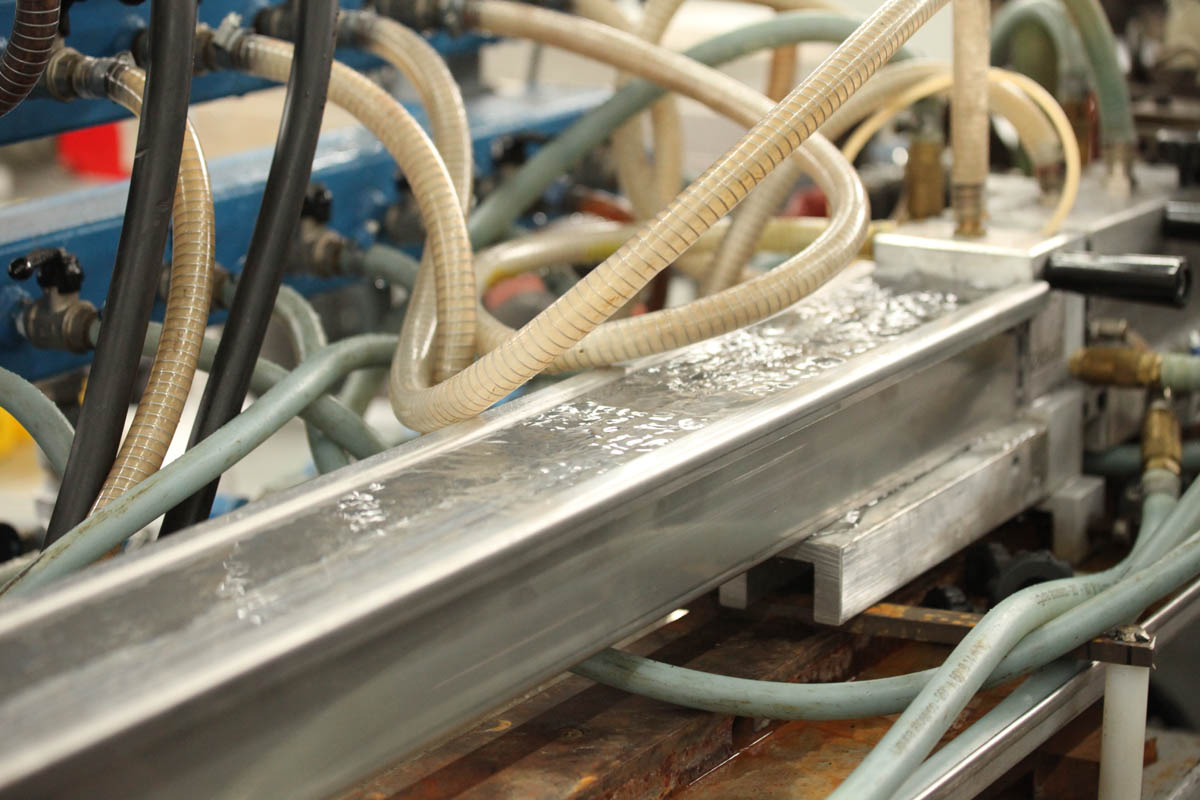

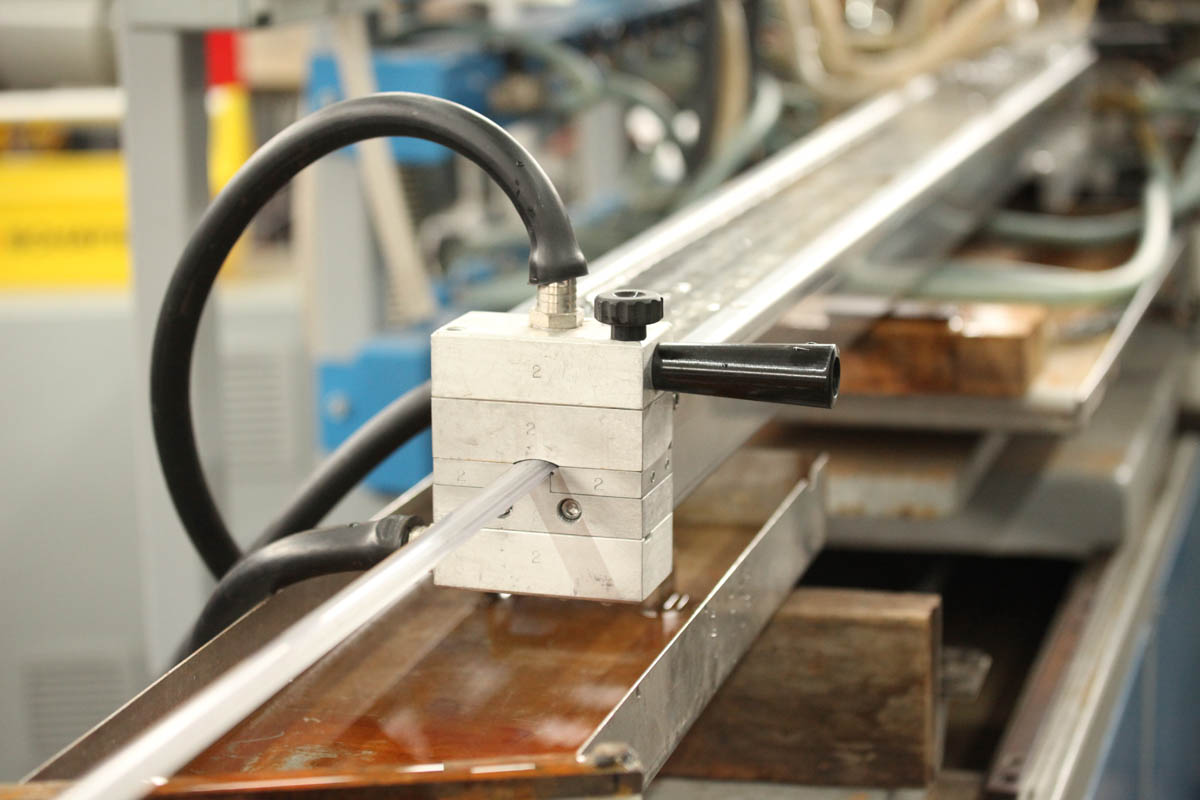

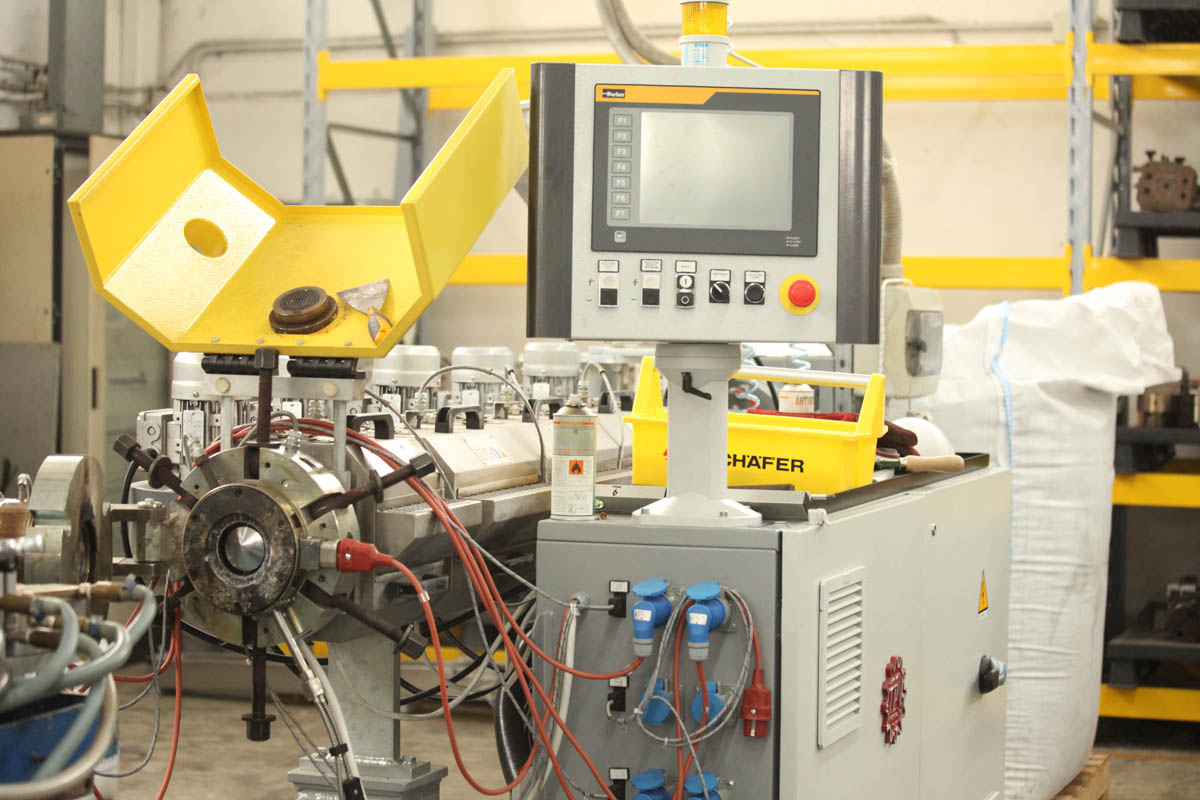

Extrusion of plastic materials, rubber extrusion, extruded profiles

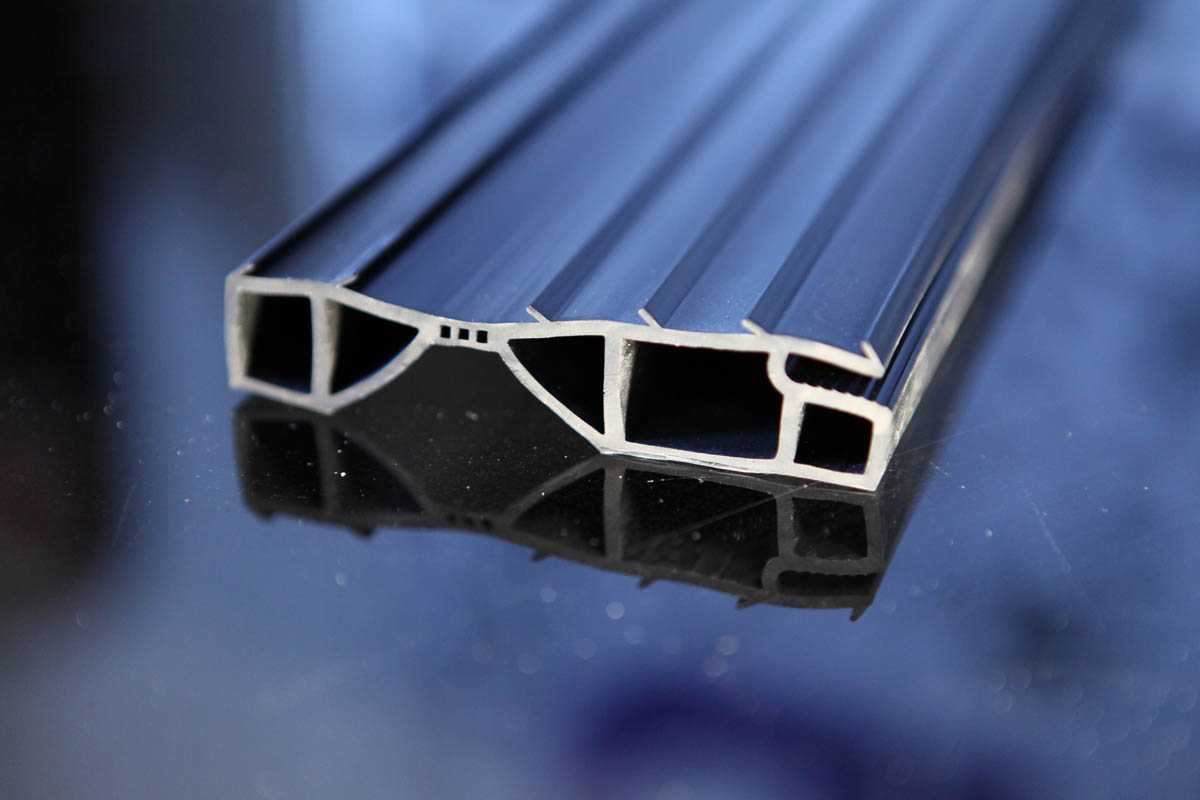

Silicon rubber extrusion

To extrude means to give a shape to raw materials.

Like raw materials, which are deformed and molded in the extrusion process, we are also subject to your demands and we process your ideas, bringing out the relevant functional and technical characteristics. We advise you in choosing the most suitable material and shape to ensure high performance.

Silicon rubber features

The silicone rubber is without any doubt the most valuable material in the world of extrusion. With its excellent properties, it finds a widespread application in the industrial sector and a growing use also in the building industry, for high quality products. All its characteristics, according to various compounds used, are:

- Excellent resistance to UV radiation, oxidation and ageing

- ottima durata nel tempo

- Excellent resistance to outdoors conditions

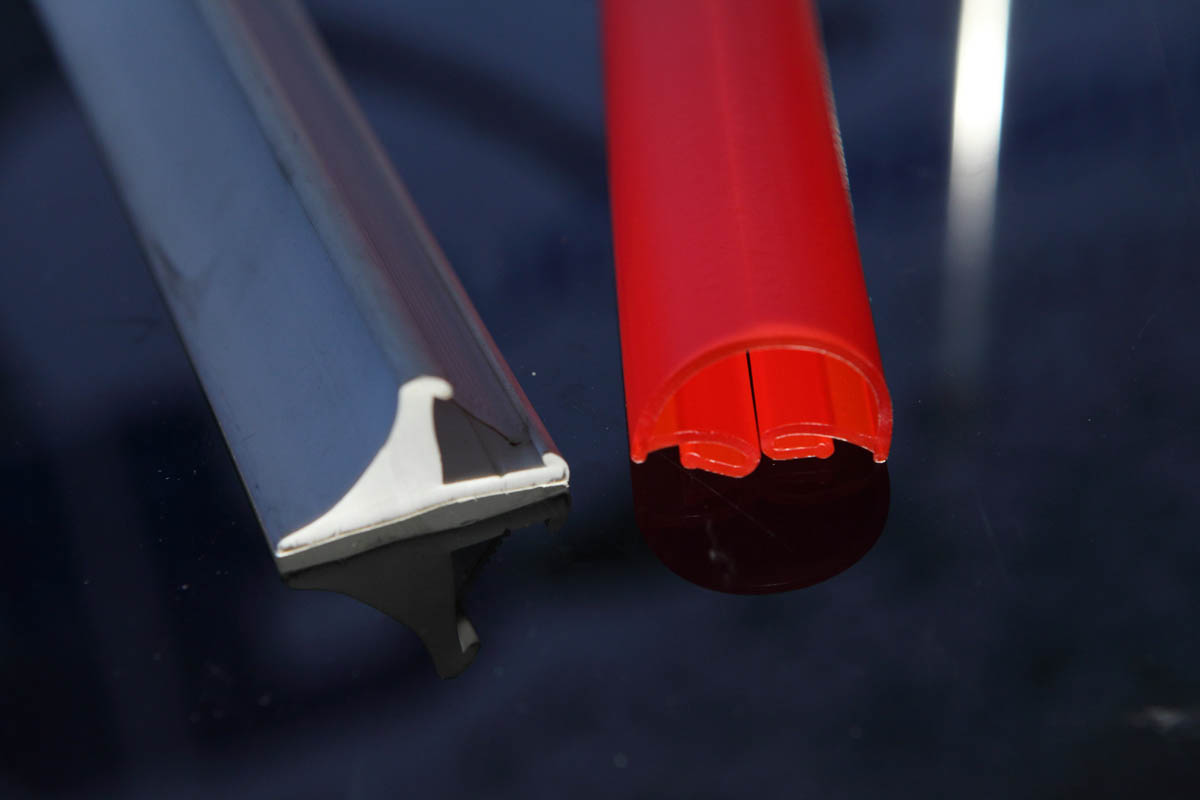

- Perfect colorability and extremely high color stability

- elevata trasparenza

- High compression sent and high resistance to permanent deformation

- Antibacterial and FDA

- Self-extinguishing VO

- Excellent dielectric properties

- Operating temperature: -70ºC + 300 °C

- saldabile a caldo con giunture vulcanizzate rette o angolari

- Odorless and tasteless

- Acoustic, thermic, electric, mechanical (vibrations) insulating

Sectors of application

We use silicone rubber to produce high quality soft seals and to meet aesthetic and design requirements. It can withstand temperatures up to 350 degrees.

With its excellent properties, silicone rubber is used in a vast range of applications in the industrial sector and is increasingly used also in construction for high quality products. This material can be made conductive-insulating, can be magnetised, can be rendered hydrophobic (hydrophobicity) and can have chrome and pearl effect colouring.

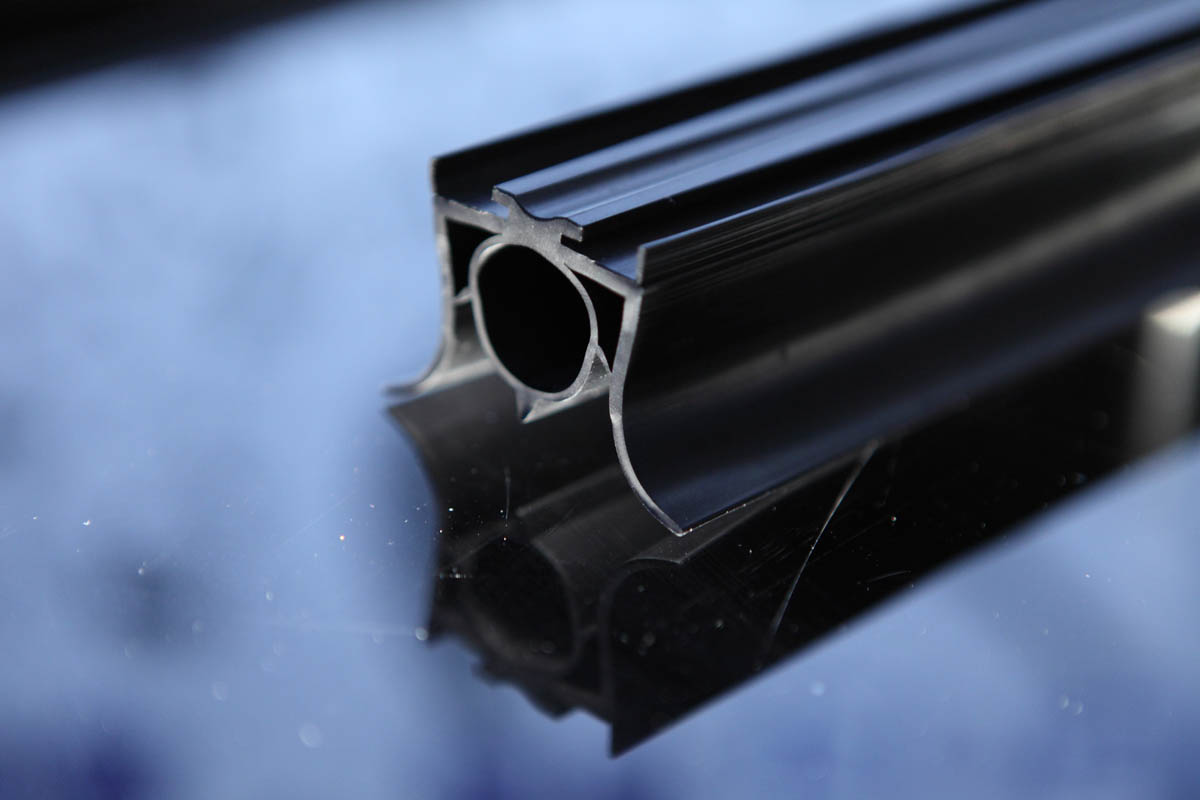

Features EPDM rubber

EPDM rubber guarantees:

- excellent resistance to heat and UV radiation

- excellent durability over time

- excellent resistance to atmospheric agents

- high compression set

- good resistance to abrasion

- high resistance to permanent deformation

- heat-sealable with straight or angular vulcanized seams

- use temperature: -40 ° c + 90 ° c

- EPDM boasts good resistance to water and glycols, aggressive chemicals and oxidation

- excellent resistance to steam up to 150 ° C

- acoustic, thermal, electrical, mechanical (vibration) insulation

Sectors of application

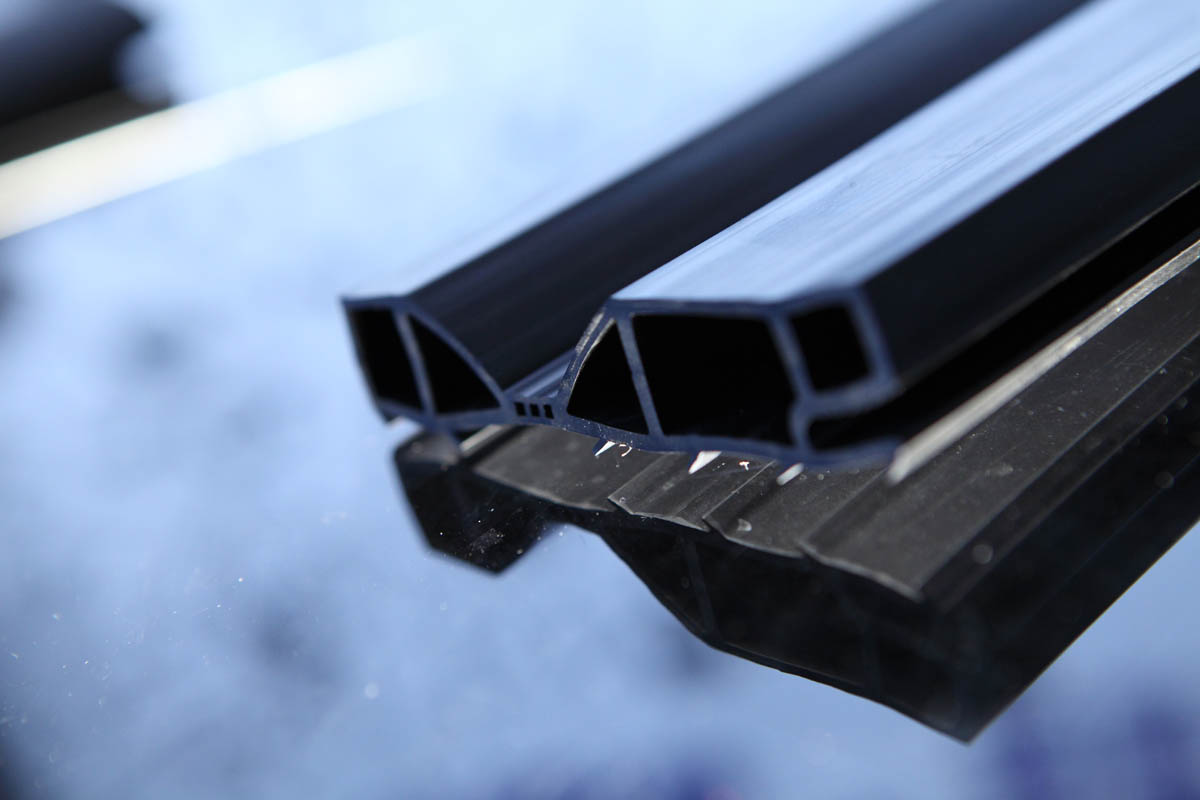

Our EPDM products have different sectors of application as they do not undergo shrinkage or variations in hardness regarding their physical-chemical performance.

In particular, our products are dedicated to the transport and construction sectors, including internal and external doors, industrial doors, dryers, etc.

In addition to the characteristics described, these materials are chosen for the various applications because they have:

- Impact resistance: from 40 to 60%

- Elongation at break: from 150 to 500%

- Heat resistance: the peroxide vulcanizates of EPDM composed in a correct way withstand hot water and steam at 110 ° C even for prolonged times without showing considerable deterioration of the characteristics

- Low temperature resistance: up to about -50 ° C

- Permeability to gases: high, however this use is not recommended

Characteristics of Plastic Materials

-

- great ease of processing

- cheapness

- colourability

- acoustic, thermal, electrical, mechanical (vibration) insulation

- corrosion resistance – chemical inertness

- water repellency

- unassailable by molds, fungi and bacteria

Sectors of application

Our profiles are specialized in finding application solutions for different sectors (construction, lighting, refrigeration, bathroom furniture / shower cubicles, etc.). Given the wide range of materials, technical specifications will be provided upon request.

The following are the standard acronyms used to identify plastics:

- ABS: acrylonitrile butadiene styrene

- PC: polycarbonate

- PE: polyethylene

- TPE: thermoplastic rubber

- SEBS: thermoplastic rubber

- PMMA: polymethylmethacrylate

- PP: polypropylene

- PS: polystyrene-polystyrene

- PVC: polyvinyl chloride

- PVCE: expanded polychlorinated vinyl

- PUR: polyurethane